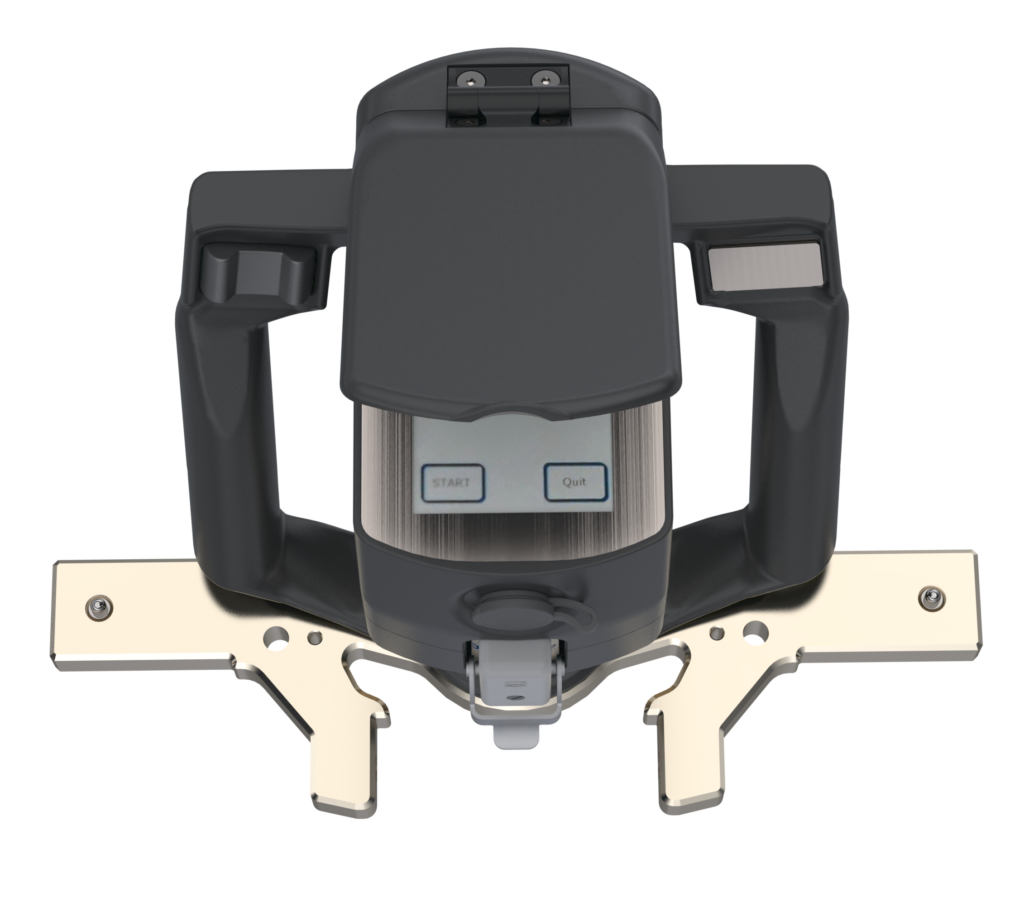

The 3S AIG XS is designed as a handy valve maintenance device and completes the product range of 3S actuators. It is with 5.5 kg much lighter and smaller than its predecessor, the 3S AIG and is offered in three versions with a peak output of up to 900 Nm. As a one-man device, it is ideal for the needs of medium and small size network operators. Torques of up to 1,800 Nm can be achieved with the 3S load amplifier.

Just like the more powerful 3S AIG, it impresses with its innovative digital electronics, which make it into much more than a simple valve exerciser. Current valve conditions can be captured and plotted as a torque curve, which also shows number of gears turned. Condition-based valve maintenance can therefore be realized.

- Objective inspection by capturing torque and number of gears turned

- Paperless and tamper-proof documentation of current valve condition

- Digital interface for importing valve master data and exporting condition data

- Optimized deployment of resources and maintenance measures

- Rehabilitation of valves instead of replacement

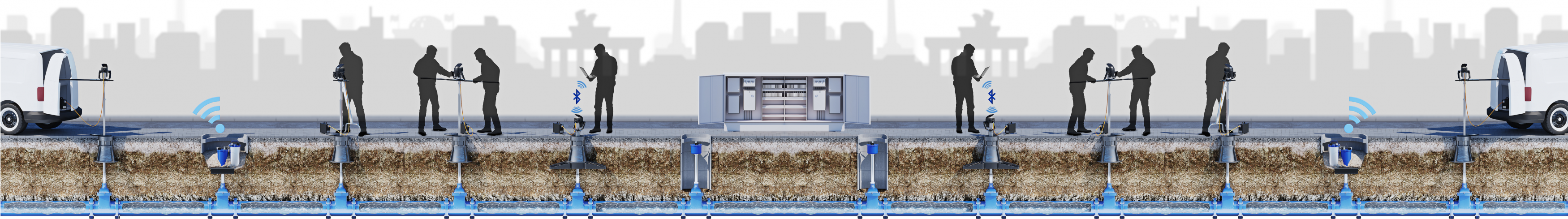

The System Berliner Kappe® makes it significantly easier to operate buried valves. It makes it possible for just one individual staff member to operate even large and extremely hard-to-operate valves – without requiring physical effort.

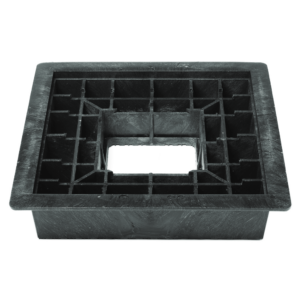

The Berliner Kappe® is a patented coupling solution developed by the Berliner Wasserbetriebe and AVK Plastics BV for the mobile actuator 3S AIG. Covered by a standard street cap, a mount is installed on a supporting plate for valve stem caps which is anchored in the ground so that it doesn’t rotate when operating the valve. The valve can still be operated manually with a valve wrench. 3S AIGcan also be used as a valve turner. The rotationally locked and grounded support plate under a standard street cap absorbs the occurring counter-torque. The usual operation by means of a slide key remains possible.

All in all, the advantages of using the System Berliner Kappe® are as follows:

- Significantly easier operation of buried valves (one person per valve of any size)

- Possibility of true predictive maintenance of buried valves

- Savings through extended service limit of valves and lower personnel costs

More information can be found here:

The AIS is a PC maintenance software that is used to evaluate the measured condition data using a uniform system. Also, this software is intended to serve paperless documentation and mobilize access to GIS data.

The "3S status light" is available for the valve status evaluation. The valves are evaluated on the basis of MOT (Maximum Operation Torque) and the number of gears.

"3S-status light":

- Green = Nominal gear count with required MOT achieved, valve is tight

- Yellow = Nominal gear count achieved, but with a higher MOT than approved

- Red = Nominal gear count not achieved, valve is leaky

The 3S AIS is doing the evaluation of the measured valve condition data: It assigns a traffic light to the valve based on the condition data measured by the 3S AIG. Additionally it is providing the fingerprint of the valve (Fig.1).

Figure 1: Fingerprint of a flap DN 400, speed 35.3, MOT 52Nm